Factor of Safety in Machine Design and Drawing

Table of Contents

What is Factor of Safety ?

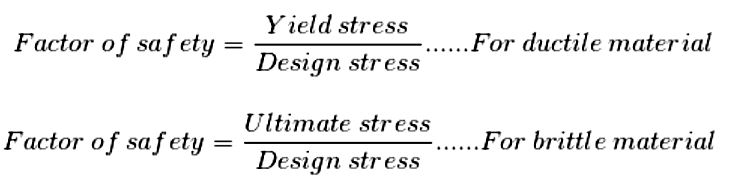

Factor of safety is defined as the “ratio of critical load to safe load”. When related to stresses it is defined as the “ratio of Ultimate stress to design stress”. The factor of safety provides the margin by which there is safety even when unseen situations arise. [PDF]

If we design with the exact breaking stress then there is risk that the component will fail as soon as any undesirable situation results in higher stress than that of breaking stress.

On the other hand, choosing higher factor of safety will result in heavier design and more material cost. So wise selection of the factor of safety is necessary so as to reach the golden point between economy and safety.

How to Choose Factor of Safety?

Following are the factors which are mainly considered while deciding the appropriate value of factor of safety.

1) Type/Nature of load:

Different types of loads demand different values of factor of safety. When the load is certain and not changing we may go for lower value of factor of safety, but for the impact or suddenly applied load or the load which fluctuates more, we need to have higher value of FOS.

2) Certainty of load analysis :

If the given load is expected to have very less variations, though uncertain, the recommended FOS can be a low value. But if the uncertainty is of larger magnitude and exact load analysis is not known it is better to go for the higher FOS.

3) Expected overloading :

Engineering objects are always subjected to overload during their use. Such overload cannot be ignored, so sufficient strength must be kept reserved for such situations.

4) Type of material used :

Certain materials like rolled Steel bars, forged materials etc are very reliable in their strength. but some materials like wood, stone, cast iron are not reliable in their strength. for lesser reliable materials higher factor of safety is chosen.

5) Type of manufacturing process :

Certain manufacturing processes does not hamper the strength prediction of material, but some manufacturing processes like welding alter the strength of material. Hence in such situations where the manufacturing process impacts the strength of material, It is wise to choose higher factor of safety.

6) Risk of life :

if the failure of the component can result in loss of human life damage to the property it is always preferred to have how a factor of safety.

7) Economical consideration :

as we go for higher factor of safety the design goes on becoming more and more bulky, as well as no cost is involved, so from economy point of view we always try to keep the value of factor of safety to an optimum level.

Suggested Values of Factor of Safety for Elementary Work

- 1.25 – 1.5 for exceptionally reliable materials used under controllable conditions and subjected to loads and stresses that can be determined with certainty – used almost invariably where low weight is a particularly important consideration

- 1.5 – 2 for well-known materials under reasonably constant environmental conditions, subjected to loads and stresses that can be determined readily.

- 2 – 2.5 for average materials operated in ordinary environments and subjected to loads and stresses that can be determined.

- 2.5 – 3 for less tried materials or for brittle materials under average conditions of environment, load and stress.

- 3 – 4 for untried materials used under average conditions of environment, load and stress.

- 3 – 4 should also be used with better-known materials that are to be used in uncertain environments or subject to uncertain stresses.

- Repeated loads : the factors established in items 1 to 6 are acceptable but must be applied to the endurance limit (ie. a fatigue strength ) rather than to the yield strength of the material.

- Impact forces : the factors given in items 3 to 6 are acceptable, but an impact factor (the dynamic factor above) should be included.

- Brittle materials : where the ultimate strength is used as the theoretical maximum, the factors presented in items 1 to 6 should be approximately doubled.

- Where higher factors might appear desirable, a more thorough analysis of the problem should be undertaken before deciding on their use.

References

- ABDULLA SHARIF, Design of Machine Elements, Dhanpat Rai Publications (P) Ltd, New Delhi, 1995

- V. B. Bhandari, Design of Machine Elements, Third Ed., The McGraw-Hills Companies, New Delhi

- R. S. KHURMI and J.K. GUPTA, A Text-Book of Machine Design, S.Chand and company ltd., New Delhi, 2000. Design of Machine Elements https://nptel.ac.in/courses/112/105/112105125/

- https://machinedesign.top/content/Introduction%20to%20Machine%20Design

- Douglas Wright, NOTES ON DESIGN AND ANALYSIS OF MACHINE ELEMENTS, Dept. of Mechanical & Materials Engineering, The University of Western Australia